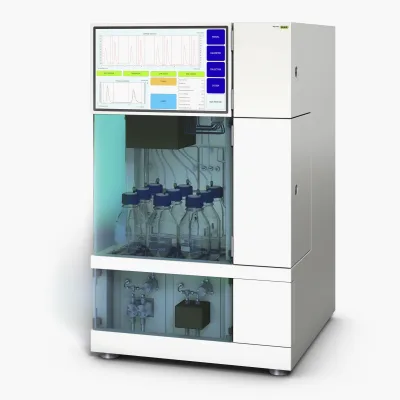

CAMAG® Derivatizer

Automated reagent transfer onto TLC and HPTLC plates

The Derivatizer is used for automated reagent transfer in the derivatization of thin-layer chromatograms and sets a new standard of reproducibility by employing a unique “micro droplet” spraying technology (patented). The Derivatizer ensures homogeneity and convenience in applying derivatization reagents, and offers other advantages as compared to manual spraying and immersion. The device is suitable for all common reagents. To meet the divergent physicochemical properties of the reagents, e.g. viscosity, four different color-coded nozzles are available, and the user can select from six spraying modes.

Key Features

Technical Specifications

Video

- Unsurpassed homogeneous reagent distribution

- Environmentally friendly and safe handling through a closed system

- Reproducible and user-independent results

- Low reagent consumption (2-4 mL)

- Hood for 20 x 10 cm and/or 20 x 20 cm plates

- Intuitive handling and easy cleaning

Derivatization means another step in the process of thin-layer chromatography, consequently causing an increase in variance. Even with a trained, expedient technician manually spraying a reagent, the coefficient of variation (CV) of the measured values rises up to 12 %. Using the CAMAG Derivatizer, the CV increases by less than 5 %, thus providing very reproducible results, equal to those obtained with the Chromatogram Immersion Device, yet consuming considerably less reagent.

The following most common reagents have been tested and validated by the CAMAG laboratory for use with the Derivatizer:

- Sulfuric acid reagent (10 % in methanol)

- Anisaldehyde reagent

- Natural product reagent

- Polyethylene glycol solution

- Iodine solution (0.5% in ethanol)

- Dragendorff reagent

- Fast blue salt B reagent

- Ehrlich’s reagent

- Phosphomolybdic acid reagent

- Ninhydrin reagent

- Copper(II) sulfate reagent

- Aniline-diphenylamine-phosphoric acid reagent

- Vanillin reagent

- Potassium hydroxide solution (5% in methanol)

- Various aqueous solutions (enzymatic solutions, etc.)

The Derivatizer is available for two different plate formats (20 x 20 cm and 20 x 10 cm).

For alternative spraying reagents and reagents that are problematic to spray, please download the recommendation list.

Plate/sheet size supported: Optimized for two plate formats 20 x 20 cm and 20 x 10 cm

Plate/sheet material supported: Glass, aluminium and plastic

Derivatization method: Automatic spraying using unique “micro droplet“ technology

Reagent consumption

- 4 ml for 20 x 20 cm plates

- 2–3 ml for 20 x 10 cm plates

Instrument operation and control: Via nine illuminated buttons (stand-alone instrument)

Operating temperature: 10–40°C

Power connection: 100–240 VAC, 50–60 Hz, 30 W

Dimensions (W x D x H): 245 x 430 x 355 mm

Weight: 12 kg