CAMAG® HPTLC PRO

Fully automated sample analysis and evaluation system for routine quality control

Fully automated sample analysis and evaluation system using HPTLC plates (20 x 10 cm). The HPTLC PRO SYSTEM (patented technology) is best suited for routine quality control of analytes extracted from complex matrices, providing reproducible and reliable results.

Designed for high-throughput analysis, the HPTLC PRO SYSTEM revolutionizes the HPTLC handling process while maintaining the method’s flexibility. With individual modules for each HPTLC step, the system processes up to five HPTLC glass plates without manual intervention – thanks to time-controlled operation even overnight.

Once the HPTLC glass plates are placed in the Module PLATE STORAGE and the vials are loaded into the Module APPLICATION, the user starts the fully automated HPTLC process by a single mouse-click in the visionCATS software. The HPTLC PRO SYSTEM uses a built-in conveyor to transport plates from one module to the other, throughout the entire HPTLC process. After analysis, the plates are transported back into the Module PLATE STORAGE.

With maximized standardization and full automation, the cGMP compliant HPTLC PRO SYSTEM is capable of delivering reproducible and reliable results, while low solvent consumption keeps operating costs low.

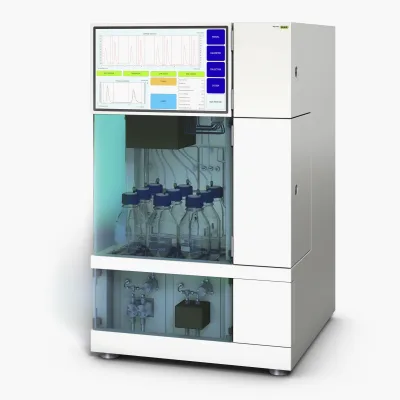

APPLICATION

The samples are applied as bands onto the HPTLC glass plate (20 x 10 cm) with the HPTLC PRO Module APPLICATION. Up to 75 samples can be applied autonomously. Precision of the applied volume, exact positioning and sharpness of applied zones determine the quality of the final result.

Key Features

Technical specifications

Link

Video

- Part of the fully automated HPTLC PRO SYSTEM

- Spray-on application of samples as bands

- Autonomous application of up to 75 samples

- HPTLC glass plates (20 x 10 cm)

- Software-controlled by visionCATS

Key Benefits

- Highly precise application zones through optimized spraying procedure adapted for each sample solvent

- Advanced cleaning capacities (two rinsing solutions)

- Improved cleaning procedure and application strategy to prevent cross contamination

- Minimized sample and solvent consumption

General data

Classification of installation and use: Class I, installation category II, protection class IPX0, Pollution degree 1

Nitrogen or clean air pressure: 5 – 8 bar (70 – 110 psi)

Operating temperature: 15 – 30 °C

Recommended working temperature: 20 – 25 °C

Humidity: Maximum relative humidity 80 % for temperatures up to 30 °C (Humidity and temperature conditions must not cause condensation!)

Plate types: HPTLC glass plates 20 x 10 cm, layer thickness 200 µm

Electrical data

Operating voltage: 100 – 240 VAC; 50 / 60 Hz

Fluctuations: ±10 % of the nominal voltage

Overvoltage: category II

Power consumption: 40 W

Fuses: 2.0 AT, 250 VAC

Max. supply current from power outlet: 8 A

Mechanical data

Dimensions (W x D x H): 384 x 550 x 510 mm

Weight: ~ 33 kg

For more information please visit: camag hptlc pro